FDM vs SLA – Which 3D Printing is Better for You?

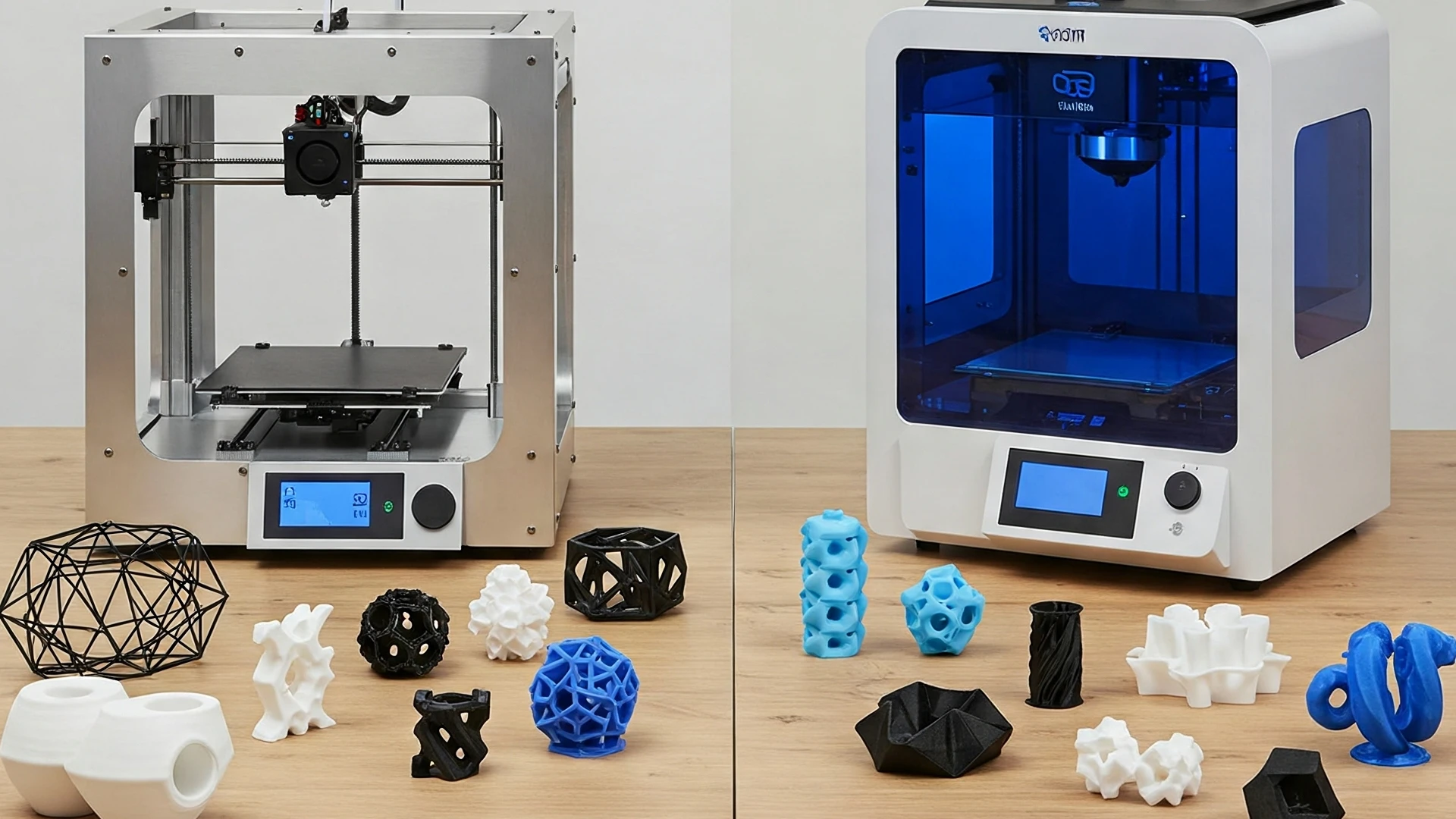

Comparison of the two most common 3D printing technologies

What's the Difference Between FDM and SLA Printing?

FDM (Fused Deposition Modeling) and SLA (Stereolithography) are the two most used 3D printing technologies. Both have their advantages and are suitable for different types of projects. While FDM focuses on durability and variety of materials, SLA offers extreme detail and smooth surface finish.

FDM printing works on the principle of layering molten plastic. The printer gradually builds the object layer by layer from materials such as PLA, ABS, or PETG. This method is cost-effective and ideal for larger parts where mechanical resistance is important.

Choosing the right technology depends on the purpose of use. Do you need a functional prototype or spare part? Choose FDM. Do you need an ultra-detailed model with a smooth surface? SLA is the better choice. We will be happy to advise you on the optimal solution for your project.

FDM (Fused Deposition Modeling)

Suitable for:

Functional prototypes requiring mechanical resistance, spare parts for household appliances or machinery, workshop tools and fixtures, architectural models, housings and boxes for electronics, larger objects (up to 30×30×30 cm), educational projects and school models.

Materials:

- PLA (eco-friendly, basic models)

- ABS (durability, mechanical parts)

- PETG (impact resistance)

- TPU (flexible materials)

- ASA (UV resistance, outdoor use)

- Nylon (high strength and durability)

- PAHT-CF (carbon fiber composite, extreme strength)

Advantages:

- ✓ Lower price

- ✓ Durable prints

- ✓ Wide range of materials

- ✓ Suitable for larger objects

Disadvantages:

- ⚠ Visible layers

- ⚠ Lower detail precision

- ⚠ Limitations for complex geometries

SLA (Stereolithography)

Suitable for:

Jewelry and jewelry prototypes, dental and medical models with high precision, miniatures and tabletop game figurines, design prototypes with smooth surface, promotional and presentation models, artistic objects and sculptures, models for molding and casting, objects with ultra-fine details (0.05 mm layer).

Materials:

- Photopolymer resins

- Specialized resins (dental, transparent)

Advantages:

- ✓ Highest details

- ✓ Smooth surface

- ✓ Precision

- ✓ Ideal for small objects with details

Disadvantages:

- ⚠ Lower durability

- ⚠ Higher price

- ⚠ Limited print size

- ⚠ Post-processing required

How to Choose the Right Technology?

Choose FDM if:

- You need functional, mechanically durable parts

- You're looking for a more affordable solution

- You don't need a perfectly smooth surface

- You're printing larger objects

Choose SLA if:

- You need a high level of detail

- You care about a smooth surface

- You're printing small, detailed objects

- You need precise models (e.g., for jewelry)

Not sure? Tell us what you'll be using the print for, and we'll recommend the optimal technology.

Get Advice